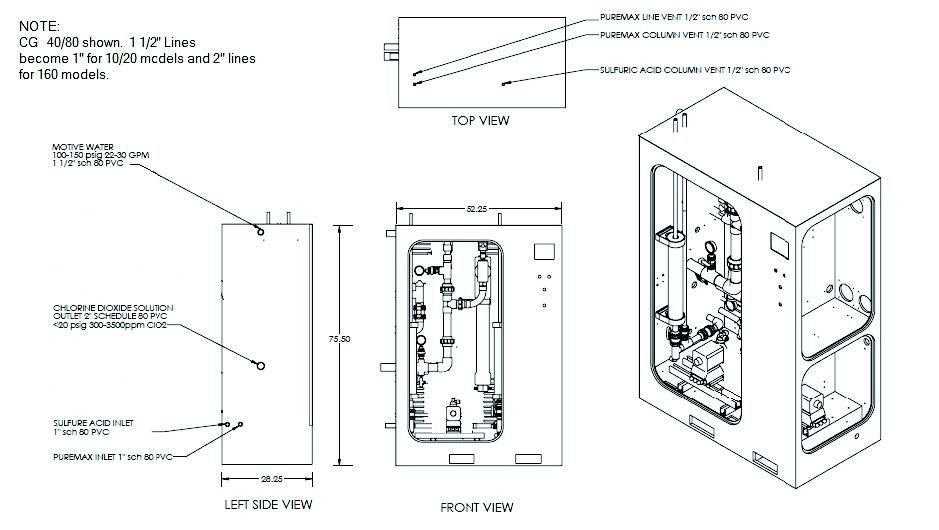

Chlorine Dioxide Generator HP Series

PureLine's HP series generator is ideally suited for applications that require high-purity Chlorine Dioxide (ClO2), such as in food and beverage production, healthcare, and pharmaceutical manufacturing. Using PureCide®E — a highly concentrated single-liquid precursor free from acid — patented electrochemical cells (no cartridges) efficiently produce a chlorine-free ClO₂ solution that is 99.5% pure, ensuring only active ClO₂ is present without unwanted by-products. Delivered on demand in a safe and efficient manner, this pure ClO₂ eliminates the need for an external storage tank.

Capable of feeding multiple dosage points simultaneously, this system can serve several applications from a single unit. Built on a common platform that facilitates cost-effective, on-site capacity upgrades to grow with facility requirements, it comes equipped with multiple safety interlocks and offers various reporting and communication options. Expert engineering and comprehensive service support make the HP series generator a benchmark in safe and reliable ClO₂ generation.

Utilising a single-liquid precursor and producing a pH-neutral solution, long-life electrolytic cells require no cartridges. Multiple control options—including flow, residual, permissive, timers, and manual controls—provide flexible operation. Customisable and scalable to deliver up to 18.1kg per day, this system offers low operating costs and an enhanced return on investment.

Technical Specifications

Standard Specifications

Parameter | Units | PureLine HP Model | |||

|---|---|---|---|---|---|

HP-3 | HP-10 | HP-20 | HP-40 | ||

| ClO2 Output Capacity | kg/day | 1.36 | 4.54 | 9.07 | 18.14 |

| Electricity requirement | 220 VAC, 1PH, 30A (<15A NLD) | ||||

| Inlet water | Clean/filtered min 350 kPa (1.89l/min – 11.36l/min) | ||||

| Precursor chemical usage | PureCideE – 6.04kg / 1kg produced ClO2 | ||||

| Co-products | 20% NaOH solution (0.037l/min-0.378l/min), Spent chemical (0.037l/min - 0.189l/min), H2 safely diluted to <0.5 vol% and RO waste (1.89l/min – 3.78l/min) | ||||

| Cabinet | White polypropylene | ||||

| PLC & HMI | Allen Bradley PLC and Colour Touch Screen | ||||

| Dimensions | mm | 1327 x 1918 x 718 | |||

| Weight | kg | 227 | |||

| Co-products | 20% NaOH solution (0.037l/min-0.378l/min), Spent chemical (0.037l/min - 0.189l/min), H2 safely diluted to <0.5 vol% andRO waste (1.89/min – 3.78l/min) | ||||

| HS Code | 8421.21.000 | ||||

Standard Inclusions and Options

Equipment | ALL HP Models |

|---|---|

| Cabinet enclosed generator | ✓ |

| Produced ClO2 solution pump | ✓ |

| Produced ClO2 break tank with pipework & fittings (1-day storage) | o |

| Cabinet air condition unit | o |

Instrumentation & Controls |

|

|---|---|

| Control Panel compliant with AS/NZS 3000, IP55 | ✓ |

| PLC control system with HMI touch screen | ✓ |

| ClO2 residual analyser | o |

| Purecomms remote monitoring | ✓ |

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

One of the highest-grade Manganese mines in the world wanted to upgrade their aging water treatment infrastructure. The site was based in an area that is susceptible to extreme heat year-round and is logistically difficult to reach. As such, achieving disinfection using sodium hypochlorite would have been problematic as the cost of transporting the liquid along with the fast thermal degradation of sodium hypochlorite would have made it an unviable solution. Considering the remote nature of the site and the extreme heat environment MAK Water proposed a containerised modular chlorine gas disinfection plant to recirculate the contents of the sites treated water tank ensuring the correct free chlorine residual is maintained at all times.

Northern Territory

Water Disinfection Systems

Related Solutions

Chlorine Gas Disinfection Recirculation

Chlorine Gas Disinfection Recirculation (CGDR) Plants are designed to automatically maintain the correct amount of free chlorine in a potable water storage tank, in accordance with Australian Drinking Water Guidelines (ADWG).

Sodium Hypochlorite Disinfection - Flow Paced

MAK Water’s Sodium Hypochlorite Disinfection Flow (SHDF) plants are designed to automatically maintain the correct amount of free chlorine in an existing reticulation line, in accordance with Australian Drinking Water Guidelines (ADWG).

.jpg&w=1080&q=100)

Sodium Hypochlorite Disinfection - Recirculated

Sodium Hypochlorite Disinfection Recirculated systems (SHDR) are designed to automatically maintain the correct amount of free chlorine in a potable water storage tank, in accordance with Australian Drinking Water Guidelines (ADWG).

UV Disinfection - Municipal

UV Disinfection - Municipal

UV Industrial

MAK Water’s UV Disinfection (UV) systems are an effective and economical means for disinfection of water.

Electrochorination

MAK Water offers an extensive range of onsite sodium hypochlorite generation plants and solutions as designed and manufactured by Electrolytic Technologies.