UV Industrial

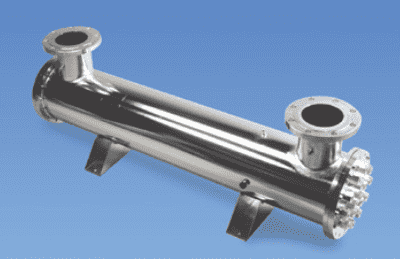

MAK Water’s UV Disinfection (UV) systems are an effective and economical means for disinfection of water. UV disinfection instantly kills bacteria, parasites and viruses by passing the water past an Ultra Violet light source, which damages the DNA of these organisms.

UV disinfection systems should be installed as close as possible to the point of end use, as the effect of a UV disinfection is only temporary – the water may become re- contaminated when stored in tanks or even in pipe work downstream of a UV disinfection system.

MAK UV systems are designed to deliver a UV dose > 40 mJ/cm2 @ 95% Ultra Violet Transmittance (UVT). The MAK UV systems are available as skid mounted units or as an addition to containerised water treatment systems.

Standard Specifications

Technical Specifications

Parameter | Units | UV-2 | UV-5 | UV-7.5 | UV-10 | UV-20 | UV-50 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate | m3/hr | 0.5 ~ 4.5 | 3.2 ~ 8.4 | 1.8 ~ 9.0 | 2.1 ~ 13.62 | 4.0 ~ 24.0 | 6.0 ~ 66.7 | ||||||||

| Pressure Drop at Peak Flow | kPa | 18 | 25 | 20.7 | 17.3 | <15 | <15 | ||||||||

| Maximum Operating Pressure | kPa | 862 | 862 | 862 | 862 | 1600 | 1600 | ||||||||

| Number of Lamps | - | 1 | 1 | 1 | 1 | 1 | 2 | ||||||||

| Standard Chamber Material | - | SS304 | SS304 | SS304 | SS304 | SS304 | SS304 | ||||||||

| Raw Water Temperature | °C | 15 ~ 40 | 15 ~ 40 | 15 ~ 40 | 15 ~ 40 | 15 ~ 50 | 15 ~ 50 | ||||||||

| Ambient Design Temperature | °C | 5 ~ 50 (-15 ~ 50 for insulated containerized system) | |||||||||||||

| Power Supply | - | AC 240 V, 1 Phase, 50/60 Hz | |||||||||||||

| Power Consumption | W | 46 | 52 | 73 | 88 | 220 | 440 | ||||||||

*Refer to UV Testing Results, based on removal of free-floating oils and grease.

Standard Inclusions and Options

Equipment | UV-2 | UV-5 | UV-7.5 | UV-10 | UV-20 | UV-50 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Touchpad Operator Control | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Lamp Run Hour meter | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Visual Alarm / Failure Status | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| UV System ON/Off Status | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Volt Free Contacts for Common Alarm | - | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Chamber Temperature Monitoring | - | ✓ | ✓ | ✓ | o | ✓ | |||||||||

| Skid Mounted with Isolation Valves | o | o | o | o | o | o | |||||||||

| Upgrade Chamber Material to SS316 | - | o | o | o | o | o | |||||||||

| 4-20 mA UV Intensity Output | - | - | - | - | o | o | |||||||||

| Remote On/Off Input | - | - | - | - | o | o | |||||||||

| Automatic Cleaning with Status/Alarm Output | - | - | - | - | o | o | |||||||||

| PLC Control System with HMI | - | - | - | - | o | o | |||||||||

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

MAK Water was engaged to deliver the process water and potable water treatment plants for the Cobre Project, one of the larger copper mine developments in Central America. As this was a Greenfield project and the exact feed water quality was uncertain, MAK Water proposed a robust process incorporating: • Chemical flocculation to improve efficiency of solids separation • Lamella clarification as pre-treatment to account for spikes in suspended solids, and • Media filtration in order to achieve the final quality of process and potable water for the site. MAK Water was selected thanks to its innovative modular containerised design, extensive experience in delivering high quality packaged water treatment plants for remote mining projects, and its ability to customise the solution to meet the project requirements.

Donoso, Colon Province, Panama, Overseas

Potable Disinfection for Offshore Platform

One of Australia’s leading Oil and Gas providers reached out to MAK Water with a unique UV disinfection replacement project for an offshore gas production platform. MAK Water was tasked with delivering a new UV disinfection solution in an existing area with very limited space requiring out-of-the-box thinking in regard to installation and on-going serviceability. MAK Water designed and manufactured a reliable solution to disinfect the potable water supply in the potable plant room, replacing a very worse-for-wear UV system installed in 1993 which was failing. We worked closely with the client to design a fit for purpose, long-term solution, compliant with the Australian Drinking Water Guidelines (ADWG) and rigid offshore engineering specifications.

Offshore, Western Australia

Filtration Plant for Hot Springs

An accommodation and wellness centre engaged with the local council and agreed to improve the quality of the water spent from their hot springs prior to discharge into the environment. To meet the stringent log reduction parameters for water treatment, a process solution incorporating a containerised Multimedia Filter (MMF) with validated UV disinfection was implemented. MAK Water worked with the client to understand their concerns regarding rainfall ingress and installed a cost effective integrated manual change over line to allow the client to perform a rainwater first flush. The solution enabled the client to meet their sustainability goals and local council requirements. This is the second plant that has installed MAK Water for similar applications for this client as it works to reduce its environmental footprint. The containerised plant reduces install time, removes the need for additional shelters and improves the longevity of the plant in harsh operating conditions.

New South Wales

Water Disinfection Systems

Related Solutions

Chlorine Dioxide Generator HP Series

PureLine's HP series generator is ideally suited for applications that require high-purity Chlorine Dioxide, such as in food and beverage production, healthcare, and pharmaceutical manufacturing.

Chlorine Gas Disinfection Recirculation

Chlorine Gas Disinfection Recirculation (CGDR) Plants are designed to automatically maintain the correct amount of free chlorine in a potable water storage tank, in accordance with Australian Drinking Water Guidelines (ADWG).

Sodium Hypochlorite Disinfection - Flow Paced

MAK Water’s Sodium Hypochlorite Disinfection Flow (SHDF) plants are designed to automatically maintain the correct amount of free chlorine in an existing reticulation line, in accordance with Australian Drinking Water Guidelines (ADWG).

.jpg&w=1080&q=100)

Sodium Hypochlorite Disinfection - Recirculated

Sodium Hypochlorite Disinfection Recirculated systems (SHDR) are designed to automatically maintain the correct amount of free chlorine in a potable water storage tank, in accordance with Australian Drinking Water Guidelines (ADWG).

UV Disinfection - Municipal

UV Disinfection - Municipal

Electrochorination

MAK Water offers an extensive range of onsite sodium hypochlorite generation plants and solutions as designed and manufactured by Electrolytic Technologies.